Responding to Supply Chain Disruption, Action Reaction

Recently Federal Reserve Chairman Jerome Powell stated, “There’s no returning to the pre-pandemic economy.” And he was probably hoping we could ignore the supply chain disruption that is causing havoc on the economy (and is an element of recent inflation.)

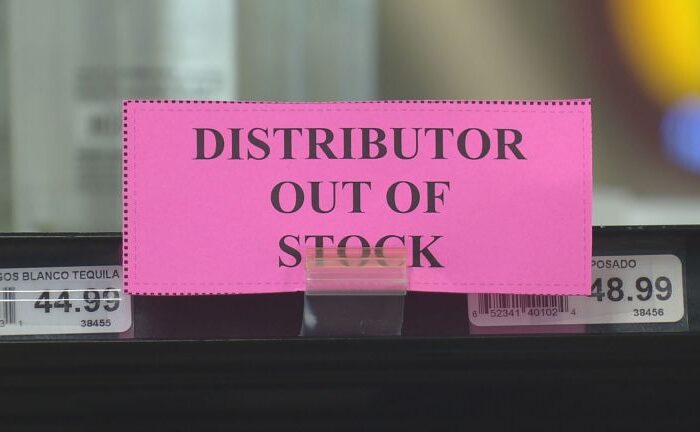

We are all too aware, and concerned, over the serious delays being created in the supply chain, especially in our industry. It concerned me enough to make some calls to various distributors, manufacturers, and manufacturer representatives throughout the country to discuss the effects, both short and long-term, this situation has created.

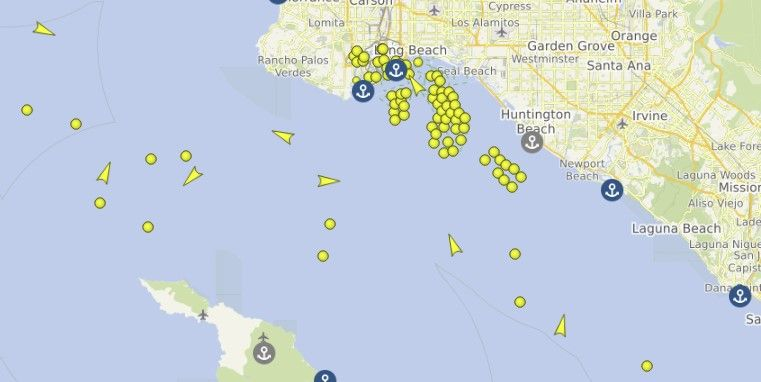

At a recent Electrical Association of Philadelphia webinar that David Gordon participated in, one participant asked “when will the supply chain disruption end” and he referenced the port congestion. Given that the Port of Long Beach recently had 54 container ships at anchor, the issue will be around “for awhile”

Given the Federal Reserve Chairman’s statement, it seems imperative to understand the effects on each element of our industry as to the causes and effects that the supply chain disruption is having on how we manage our businesses now and in the future. And part of it may relate to how we choose our allies. Perhaps it is far more important to understand and react to the changes rather than merely accept them as permanent.

Manufacturers

The manufacturers I spoke with had very different reactions and strategies. Some are focused on orders in-house and filling each as quickly and economically as possible by producing product on a first come; first served basis. Filling the pipeline and production schedules on “A” items as needed and filing in on others when necessary.

Another was only currently accepting orders from full-line distributors and not setting up any new distributors, or servicing non-full-line distributors, until such time as they are able to satisfy current customer’s needs while building up their inventory.

Another was only allowing customers a percentage of the orders, and specific items, based on previous orders they had placed.

I was also told by multiple distributors that another manufacturer on some specific products had decided to support their DIY channel rather than the electrical distribution market until they “caught up with production and their DIY commitment”, leaving “some” in the electrical channel to find alternative sources for these selected but necessary products. There was the belief that “these customers will come back to us when we’re ready.”

Manufacturers appear to have varying approaches and, in some instances, are making decisions that may have longer-term impact on their channel relationships. In some instances, this could be beneficial for the supplier with a more refined go-to-market approach. In other instances, the result may be further distributor perception of the product offering as a “commodity” and there be a loss of brand / supplier loyalty (or brand preference).

Distributors

Distributors likewise had different strategies to cope with the shortages and increased pressures of getting product.

Some said the cost of maintaining product in stock and making deliveries was becoming too high given “guess work” on when orders would be filled and slower counters, so they have focused more on job business and direct shipments. They discussed raising minimums for deliveries but felt too many customers would get upset should they issue a statement to that affect.

Two other distributors claimed they had increased inventories to satisfy customers, and the customers were willing to pay the additional charges for having immediate access to product regardless of whether the products were supplies, gear or lighting. In other words, they sought to increase their margins. These distributors did admit they had become “less loyal” to their “preferred” manufacturers and more concerned about getting inventory when needed. They were more interested in having product for their customers than end-of-year rebates from manufacturers that could not supply product when needed. They also admitted placing multiple orders with different manufacturers, anticipating careful inventory control and they could cancel outstanding backorders when necessary if their supplies became too heavy.

Contractors & End-Users

Contractors I spoke with understand the shortages and are trying to do a better job of scheduling speeding up their procedures. They are beginning to understand that merely wanting a product does not mean now they can get it by ordering and picking it up. They also know that pricing is changing too often and are protecting themselves either with future orders or sitting with salespeople and reviewing their schedules for jobs. They are now making exceptions on pricing commitments and against penalty clauses for not finishing on a specific time frame.

I spoke with a major home builder who recently contacted the president of a major utility and stated that they could not sell homes or multi-family dwellings because of the utility’s older specifications which limited the manufacturers for a specific product. He explained that he needed to change from a hard, single supplier spec to a soft-spec to ensure that material was available to complete projects. The call changed the specifications for products not risking safety, merely ordering more “vanilla” product.

The commonality here was that distributor salespeople and manufacturer representatives were talking with their customers, keeping the lines of communication open and having transparent conversations.

Manufacturer Representatives

What about the manufacturer’s representatives? Their issue is spending more time on expediting than selling. However, they admitted their inside sales teams are now more imperative to their success by getting answers to customers that many of their manufacturers are unable to provide on a timely basis, if at all. As one said to me, “please excuse my selling time when I should be expediting.”

Outside salespeople at sales reps are unanimously doing more specification calls and have found them more effective than previously. These interactions range from product recommendation (“sales”) to being an ongoing, trusted, communication link to the end-user who is distributor agnostic. Issues that they have been helping end-users with include making them aware of product delays, advising of supplier price increases (without specifying the price), sharing new product information that is “solution-oriented” and productivity enhancers, providing spec sheets and more.

End-users / contractors are finding that dealing with the salespeople (factory or reps) get them faster answers and they believe better positions themselves with the specific manufacturer.

Reps also claim they are doing more of the end-user calls because it is expected from their manufacturers and they claim they are often getting less loyalty, or support, from distribution who is forced to go to multiple manufacturers for product (due to product availability or pricing). It was mentioned multiple times that the manufacturer representative’s salesperson is often a better barometer of support than the distributor and working with them directly is far more likely to get results.

Not one of the people I spoke believed the supply chain issues that we’re currently facing was a short-term issue to be resolved by the end of this year. Everyone believed this was at minimum 6-months to a year more of shortages, manufacturing and shipping issues.

Supply Chain Disruption, Not a Short-term Issue

Whether you believe the Federal Reserve Chairman or not, the reality is the way we did things has certainly evolved. It may be up to each of us to not only understand action and reaction, but to create an understanding of expectations now and moving forward. The former president of a wire manufacturer once told me, “They are angry at us now, but once we have it at the right price, they will forget.” Eleanor Roosevelt said “a woman is like a tea bag- you can’t tell how strong she is until you put her in hot water.” We are all in “hot water” now. What will we be like from this moving forward might just be as critical? Today’s decisions may redefine some company’s strategies.