Opportunities Created by Shortages and Allocations

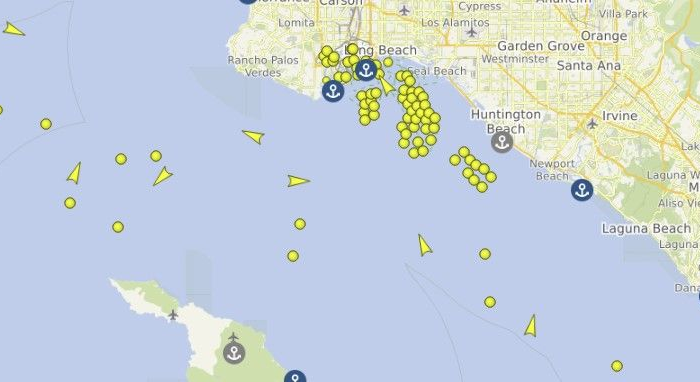

Given today’s supply chain disruption from material shortages, lack of truck drivers warehouse staff, and docks full of unloaded material, culminating in manufacturers many turn defensive, tell customers “material is coming, just wait” (similar to a rolling airline delay) and hope for the best and that the project, or order, doesn’t get cancelled.

However, given no end in sight for the issues above, some are looking at others’ misfortune as opportunities.

Allow me an example from my prior agency.

It started 4 ½ years ago when we tried to get a product approved by one of our major utilities. Regardless of what we offered in specifications, samples and both contractor and distributor referrals, we were unable to succeed.

Recently, after contacting a few contractors, builders, and developers the agency became aware that many projects were being delayed due to this product’s delivery from competitors. The agency again pursued the engineering group doing the specification and this time, were granted an audience. Sales perseverance!

The agency, with the support of the manufacturer, again submitted the product for approval. A calling campaign was organized by the agency with builders, contractors and distributors contacting key utility staff to state that the agency, local distributors, and the manufacturer had product that would be available and would put a plan into action immediately.

The agency met with the standards people and purchasing and shared a plan that would enable some of the very projects delayed to be activated.

Consider, the builders could not sell properties, contractors were not being compensated, and the utility was not able to sell power. Remember, money talks.

The cause was significantly improved when one of the national home builders contacted the president of the utility and stated that they were aware that there was a product that would meet standards and available. The utility president, who was on vacation, contacted the standards committee stating he wanted this project elevated in importance without affecting the quality of the connections.

There were extras the utility wanted included which the the factory could not be accommodate because it was already at production capacity. Like many manufacturers nowadays, they were unable to build thevinventory as everything being manufactured was being sold. They were producing and selling every “vanilla” unit they manufactured. The agency offered, for a fee, to prefabricate the product with those items considered “accessories” that did not affect the electrical operation. UL was contacted to make sure this was the case and received their approval. Because multiple distributors support the manufacturer and the utility, it was felt that the pre-fab service needed to be handled by a third party rather than one distributor.

The utility then sent the approval out to all their field people and contractors working in their territory with the agency’s telephone number as the contact. Anyone needing a distributor stocking the product now approved contacted us. The manufacturer was happy for the approvals and sales, but so were the local stocking distributors who were notified of the changes, the contractors and builders. Plus, the agency received the calls from users who received its linecard that and this led to additional sales for additional products and manufacturers.

The immediate need was met, now the manufacturer wanted to forecast demand. So, once again, the agency met with the utility’s engineering group to try forecasting future demand. They were confused. According to them, and I know this is simplistic, contractors know well in advance when this product was needed for each house, multi-family dwelling or commercial application. They asked “Why do they wait till they need it and go to a counter or make a call to a distributor knowing of all the shortages?” Their question, and challenge to the agency, was for more planning to occur in the process.

An interesting challenge. How often, on larger projects, do distributors, and/or agents, sit down with the customer and offer planning for the products to be available when needed? Are those customers willing to pay prices in the future for storage? Is the manufacturer able to hold pricing and for how long?

All of these questions certainly need responses, but we may be in this shortage world for a while, and these questions were recently brought up at a recent NECA meeting. The contractors also complained about local inventories, but they also admitted part of the issue was their inability to plan with distributors or manufacturers. I know many do try discussing future needs, but now senior management of users are involved, and not just purchasing departments or job foremen … people who focus on larger business issues that involve satisfying their customer and revenue generation. As one contractor told me, “we often plan for switchgear and lighting, but we have not for supply products.”

It is even more important to communicate and work together with trusted allies during this process. Margins can be improved with planning if there are results that prove all can benefit from it. The utility knew there would be extra cost in the prefab work done and was willing to pay for it. Without planning, deliveries were running 30 weeks or more. We were able to electrify their jobs in 2-3 weeks and, with planning, product will now be available for their jobs when needed.

At a time when many have determined being very selective has few rewards and purchasing generically offers more possibilities, perhaps if we have the right relationships with those willing to reward selectivity and loyalty might prove beneficial to everyone.

7 Takeaways to Help Address Product Shortages:

- Sales persistence pays

- Local market knowledge and local relationships can spot opportunities as well as garner support for specification change.

- Specification change doesn’t always mean performance change. Sometimes it comes down to showing “equal”

- Talking with the customer can develop mutually-beneficial opportunities

- When customers value something, they may be willing to pay for it (as in the case of pre-fab services). The key is valuing your contributions.

- Engaging in planning discussions can improve processes

- And yes, you need a viable solution as an alternative to the product shortage in question

In this instance supply chain disruption and product shortages created an opportunity for a competing product. Just because there is a product shortfall doesn’t mean that there aren’t opportunities … for others!