Managing Shortages with Relationships in Mind

picture from https://denver.cbslocal.com/2021/10/13/product-shortages-supply-chain-covid/

Many of us “old-timers” have previously gone through product shortages in this industry. However, I never recall so many products being involved at the same time. How companies deal with this may have longer term affects, however, than in the past.

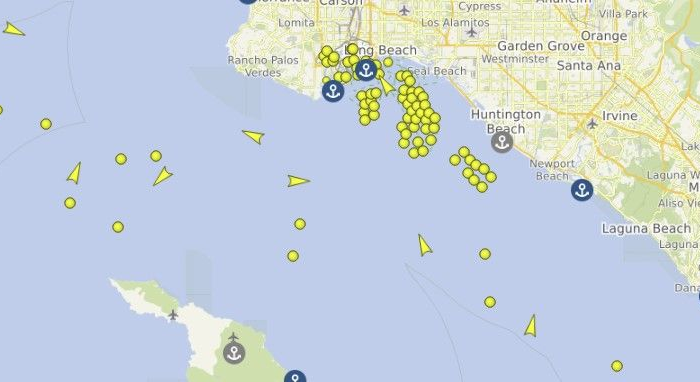

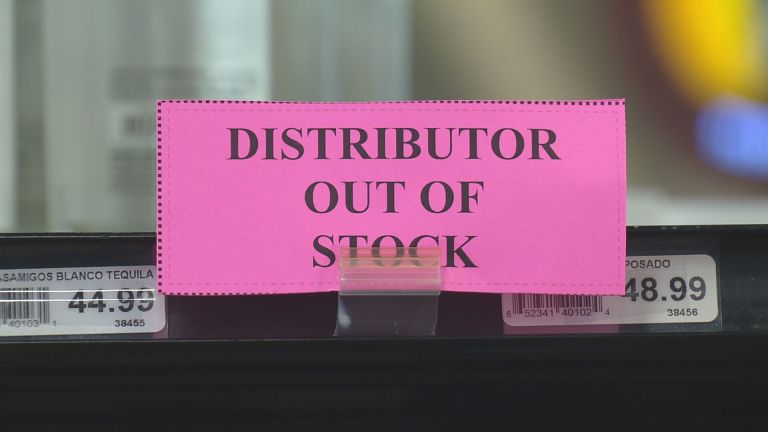

The one thing we know about any product shortage, or delay, is that someone will be disappointed. That is the end result, whether the shortage or delay is unavoidable or not and is called force majeure, the bottom line is that ship dates were missed and projects cannot be completed (and sometimes it is compounded by increased costs.)

Let’s look at some things we’re hearing.

From Manufacturers

How shortages are being resolved, or customers prioritized, to reduce the backlog and keep customers satisfied certainly will be remembered. What are some of the strategies being currently employed?

From talking to reps, manufacturers, and distributors, we know of a manufacturer that decided, for one of their specific product lines, to support the DIY market before that of electrical distribution. From a business perspective, probably makes sense. The retailer (be it Home Depot or Lowes) may purchase more than a distributor (but all distributors?) and may even be more profitable or easier to do business with, but, the manufacturer may have been more concerned about being penalized by the DIY chain for a late or short delivery (perhaps something distributors should consider?) Perhaps this manufacturer was concerned about a black mark for the next line review? The result, according to distributors of this manufacturer, was to find alternatives for this product line. Some distributors reported that their search resulted in them buying more SKUs from the new manufacturer. They were forced to find other suppliers as the product was essential to their business. Their customer needed to be served. These distributors also shared that the manufacturer made their “support decision” with no regard for those who were completely loyal to this manufacturer or those using the manufacturer viewed as periodic. It was a choice of which customer, or channel, to support at the time.

This may be a singular occurrence as, more commonly, manufacturers have gone to an allocation model such as limiting the purchases of product from distributors make based on a specific formula such as “the average sales per month purchased by the same distributor in 2020.”

More manufacturers are now also not accepting backorders. When the orders are placed, product not available is cancelled. Should the cancelled items reduce the order to below minimums for freight, the customer is charged freight or, with some manufacturers, they are notified, leaving the distributor the choice to either add available items to the order or pay the freight charge.

Those accepting backorders are now, in more cases, charging the new price at the time of shipment rather than the price at the time the order is placed.

After a year of learning the definition of “supply chain disruption”, we all understand the many issues as to why manufacturers are in this position and that they certainly could not see these issues coming and are desperately trying to catch up although many are commenting that this will continue well into next year. Each is trying their best to satisfy as many customers as possible within their capability of performing.

The challenge, according to distributors and reps, is the quality of communications from a number of manufacturers. Most would be happy with some transparency and manufacturers being proactive with their communications.

This then gets to the question of longer-term affect. A question to distributors – if you were previous loyal to a manufacturer and that manufacturer is no longer taking that into consideration when they are making decisions on material allocation, or is supporting other channels, , what happens when product becomes more available?

From Distributors

The rising cost of products makes distributor inventory significantly higher and far more expensive to maintain. The distributor that relied on selected manufacturers for products now is forced to add suppliers and is incurring increased costs for additional shipments, receiving, invoices, and related expenses including space in warehouses. Distributors, like manufacturers, are also facing shortages of workers included in the warehouse and truck drivers. They too often are forced to rush inexperienced workers into the efforts to satisfy customers causing more errors and less efficiencies.

A distributor told me the added costs make it more profitable for him to write job business that ships directly to the site rather than bring product in and get it to customers when needed. This was echoed by others I had spoken. The consideration that customers were willing to accept price increases (if they could even get product when it was needed from stock) was included in these calculations of profitability.

Imagine the issues that will occur to volume incentive programs when numbers will not be hit achieved due to product taking months after orders were placed. Distributors will want their goals reduced and accommodations made to them, or for next year’s goal to be reduced! Certainly, higher pricing may make hitting these incentives easier, however I am sure expectations of some may be that all need to be flexible, leading to further problems.

Selling product? Distributor salespeople are reporting that, even with customers more open to seeing them, conversations center more on getting product than being introduced to new product.

Another issue not necessarily addressed is the elimination of manufacturers being purchased by competitors. Although it has been going on for years, I cannot remember the magnitude of those done in the past 2 years leaving fewer choices for distributors and customers to buy.

Try purchasing wire, conduit, underground enclosures, boxes, fittings and more of the most popular supply items. So many are purchasing from the same manufacturers further reducing distributor margins. This has also led to difficulty with distributor salespeople willing to help specify product that their competitors can also purchase. With price increases and supply chain issues, there is little focus on building brand and promoting a value proposition. Essentially it becomes the end of alternatives (or only a few alternatives). It’s no wonder that independent manufacturers, especially domestic producers, are finding opportunities to take share.

From Manufacturer Reps

When I was a NEMRA Chapter President the Philadelphia chapter had 28 members including one lighting representative. Today, locally, there are fewer than 10 supply reps in the area. This leads to manufacturer issues when searching for quality representation in a territory.

Where do manufacturers want their reps to be? Many reps I have spoken state that most of their time is now spent expediting product rather than selling it. It is not that this is what their expectations are; merely this is what they are being forced to do. Outside salespeople need to get out to promote products, when possible, especially now because as stated above, it is their efforts that need to be utilized when distributors will not. The change in rep expectations to call on end-users / contractors and provide more customer service and administrative reports has not led to an increase in commission rates, thus resulting in representatives taking on more manufacturers to maintain their people and services.

A manufacturer told me that their reps are making more money due to increased pricing. True, but the shortages do not allow the same quantities or footage to be sold, and the change in rep functions have not seen a change in those commissions. Further, pricing has risen for all, so all should be making more. But, like the adage says “this too will change”. Maybe not significant decreases in everything, but not continued increases either. Commissions are needed to hire the additional associates for these additional responsibilities. Is there a difference in commissions from manufacturers to those representatives who are also calling on engineers, OEMs, contractor, and MRO accounts in addition to the distribution channel versus those who primarily focus on distribution? Some reps do; some do not, but most are compensated equally.

We’re also hearing about manufacturers cutting expenses and some curbing hiring (some cutting). When asked why, inevitably we’re hearing “finance”. The prevailing thought is that manufacturers are producing all they can, benefiting from higher selling prices and still selling, so why incur expenses to grow the business. The word is that finance is in control to optimize the bottom line.

There are opportunities available now! Getting out to see customers who were not purchasing your items and supporting others not getting material are available. Going on offense is a significant opportunity. It is one of the advantages of knowing your customer’s needs, habits and having relationships.

Another experience during shortages occurred to me years ago during a significant wire shortage. A local distributor gave me a wire order on a Friday after 3 years of calling on the owner. I visited with him the following Monday at his office. I thanked him for the order, but had to tell him that our agency would not be able to accept it. We determined, based on the wire pounds we were allocated, to support our supporting distributors (at this time allocations were to an agency, not to a distributor … there was a limit on what we could sell) Expecting an issue with him to our strategy, he got up from his desk and walked over thanking me and telling me that when we would agree to sell to him, he would make us his major source. He stated that if the manufacturer he had been loyal to him was loyal, he would not need another. We eventually had enough material allocated to us and he did become a customer … and one of our top 5 customers over many years.

Going Forward

In my opinion the challenges of product shortages and our overall ability to manage them still comes down to relationships and communication. If we are to expect our customers to be loyal to us in the future, we owe them to communicate effectively, share information and be consistent in our strategy.

Food for Thought

You, and your customers, have gone through much over the past couple of years. Do you know how well you’ve performed / reacted in their eyes? We’re currently deploying our customer satisfaction survey methodology for a client, and we’ve added two questions … one about how well they’ve performed in communicating supply chain disruptions and price increases and another regarding how customers felt regarding their response to COVID. Asking customers their input … a novel idea! You’d be amazed at how they want to be asked to contribute to your success … and they feel more valued as a customer.

Want to learn more? Ask us about our customer satisfaction strategies for distributors, our distributor satisfaction process for reps and custom approaches for manufacturers.