The Right Inventory, and Pricing, Drives Sales and Profits

Managing your inventory is the key to driving both top-line sales and gross margin performance in 2025.

Managing your inventory is the key to driving both top-line sales and gross margin performance in 2025.

I had a discussion last week with Brent Johnstone from ACTvantage for an article I wrote for our sister HVACR Trends publication about ways distributors can drive margin and sales improvement. For many the prevailing thought of most distributors and manufacturers in the B2B Distribution Channel is:

- Growing top-line sales above market usually requires some discounting and the sacrifice of Gross Margin percentage.

- Increasing prices can mean a net short-term gain, but it will slow down top-line growth in the long term.

I know that the above statements have some hyperbole to them, but in general, I think they are accurate in terms of how most associates in the electrical channel think. If you ask for higher prices, you’ll likely decrease the amount you sell, and every job is a rock fight.

However, I believe you can achieve margin expansion and above-market sales growth because most channel partners have process gaps to address.

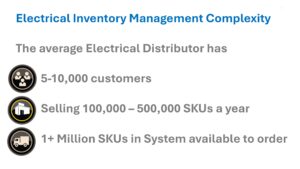

Distribution is the proverbial leaky bucket because of the complexity of the process.

This graphic illustrates the complexity of managing the intersection of pricing, inventory, customer, and supplier data to have the “right inventory” mix for electrical distributors.

This graphic illustrates the complexity of managing the intersection of pricing, inventory, customer, and supplier data to have the “right inventory” mix for electrical distributors.

This complexity always creates areas where, with data, you can improve your business in three key areas.

- Purchasing (buy-side) and buying better – Almost every channel partner’s sales team thinks their team is buyers (restockers) vs. purchasers (strategic supply managers).

- Pricing (sell side) to win more often – Sales teams typically agree that their teams do not deliver a “market price” that allows them to win without discounting.

- Inventory levels (you need it, we got it) – Breadth and Depth of Same-Day and Next-Day Inventory is where most sales leaders in the channel feel their business needs improvement. In this article, we will cover some critical areas for consideration; let’s start with this universal truth in distribution.

If your customers believe you have the right inventory to serve them, it will supercharge your Sales and Margin Growth.

For Electrical, having the right “Same Day” inventory is a very important factor for your contractors. When contractors are at a service call or have a change on the electrical for a project, they analyze what products they need and place an order with a distributor who has them. If you can improve your “Same Day” inventory, you will win more often at acceptable margin levels.

We can argue how times have change, and same day inventory needs may be declining in importance for Electrical. I think we all can agree that if customers, reps, and manufacturers start to hear and experience that XYZ distributor is having issues with out-of-stocks that bad news spreads like a wildfire. If you get that out-of-stock reputation based off of poor in- stock performance, it takes a lot of work and time to reverse that perception. Plus, until you do reverse that market perception you will be at a competitive disadvantage.

So, where do you start on a journey to improve your inventory?

We recommend you follow some proven steps. (Thank you to the team at ACTvantage for sharing some of their process for improvement)

ACTvantage Playbook – Inventory/S&OP (“Fusion”) Decision Tree

Category Level

I love this approach; it offers a framework you can adopt in your business. ACTvantage shared:

- “Start your analysis at your Category level” – e.g., Controls, Motors, HVACR equipment, Parts and supplies, etc.) and then dive deeper.

What are the key factors driving your Inventory Rank metrics

- Look at your GMROII vs. other categories and what it would take to improve. GMROII is your Gross Margin Return on Inventory Investment, a ratio that shows how much gross profit you generate for each dollar of inventory you carry.

- Break GMROII into constituent components for a deeper dive:

- Look at GM$ levels and trends vs. other categories (and relative impact on GMROII) and what might be driving underperformance.

- Examine your relative sales $ levels and trends (and impact on GM$)

- Look at relative margin levels and trends (and effect on GM$)

- COGs levels and trends (Are you experiencing higher per-unit costs/inflation from suppliers?)

- Pricing trends: Do margins follow a typical pattern, or is there something odd that could indicate competitive dynamics not present in other categories? Look at typical pricing factors to see if they align with expected margins: demand elasticity, Unit Prices, product “visibility,” and availability

- Examine your inventory levels (% of D inventory and its relative impact on GMROII)

- Once you’ve analyzed each component of GMROII, break your inventory into “sub-buckets” within each inventory rank (A/B/C/D) and engage best practices to determine what it would take to improve inventory ranks within each bucket (i.e., what combination of sales effort, supplier negotiation, pricing, and inventory reduction).

- Break GMROII into constituent components for a deeper dive:

- Another step in this process will lead you to inventory workflow decisions that tie to the number of customers that purchase each SKU.

For example –

- You will want to analyze D inventory that customers have not purchased in the last 6 months.

- You’ll also want to investigate “at risk” inventory purchased only by one or two customers.

This inventory analysis may lead you to supplier and customer discussions/negotiations. It may also prompt you to designate certain SKUs as “non-stock,” modify reorder points, and otherwise reduce D inventory to move some of that investment into A & B inventory.

Without understanding those intersections and making data-driven decisions, your inventory optimization process will have gaps.

Process Mapping

It all starts with the process. Once you map and understand your inventory processes, you can take steps to look one level deeper once critical factors are isolated.

Then, you can work on whether you can improve your inventory with better supplier selection, better supplier negotiation, analysis at the customer level, improved pricing, and so on.

It is difficult to do this in an internal silo, in my opinion and experience, without looking at best practices from experts like ACTvantage (Analytics Tools & Training for the Distribution Industry). Companies like ACTvantage and others have programs and best practices to help boost performance in multiple functional areas.

Improving inventory planning and pricing is more than a tactic or initiative. The first step, before running out and getting involved with a company that sells software (you subscribe) and outsourcing the responsibility to them for a portion of your business, is to have a corporate philosophy that executive management, sales, purchasing, and others buy-into. From these you can consider the process. Outside help can assist in developing the philosophy … but you own it and need to sell it internally.

I’ve found that ACTvantage was effective in some of my journeys. Feel free to reach out if you’d like to discuss.