Cross Reference Tools Can Win Electrical Market Baskets

Recently I saw information promoted by a company called Mydatafactory as I saw their advertorial targeting the industrial distribution industry. It intrigued me as it spoke to how industrially-oriented companies could compete more effectively versus the large distributors. Essentially, this is winning market baskets. To do this you need an effective cross-referencing tool that can quickly do conversions so you can do a quote.

Recently I saw information promoted by a company called Mydatafactory as I saw their advertorial targeting the industrial distribution industry. It intrigued me as it spoke to how industrially-oriented companies could compete more effectively versus the large distributors. Essentially, this is winning market baskets. To do this you need an effective cross-referencing tool that can quickly do conversions so you can do a quote.

And yes, the electrical industry is not the industrial supply industry, however,

- Many electrical distributors serve industrial customers and especially serve customers’ MRO needs.

- Electrical distributors pursue institutional accounts (hospitals, education, etc…) for their MRO supplies.

- MRO customers are known for asking for “market basket” quotes and for contracts.

- Further, there are contractors who bid out frequently purchased items on a quarterly or semi-annual basis. Their goal is to either have product category price agreements (they call it contracts but there are no commitments!) or dedicated pricing.

The result is lots of working developing pricing … and inevitably it involves cross-referencing SKUs to lines that “you” carry because, if you leave too many lines blank, you lose / are disqualified.

This is the same process companies such as Wesco, Grainger, SupplyForce, Vantage Group, Graybar, Fastenal, and others use to pursue national account agreements.

Rarely do you see software companies that understand distributor issues. They typically understand the issue solely from the perspective of how their tool can help distributors. Not to say most are parochial, but they are and should be. After speaking with them I learned about their product, which addresses a niche that is a time sucker for distributors … cross references, especially when quoting market baskets.

Given their understanding, I asked Timo Bouwers to share more. See if you agree.

How Large Distributors Get Beat

Within industrial distribution there are a couple of large players. Let’s call them G, F, and M. With massive product catalogs, strong brand recognition, and national reach, they seem difficult to beat. But scale isn’t everything. Smaller and mid-sized distributors can absolutely compete – and win – by using their agility. In many cases, it’s the exact reason why these distributors are winning deals against the bigger players today.

I’ve spoken to many distributors over the last few years, from smaller businesses to massive international companies, and one thing is clear: scale is not everything. Large distributors have impressive reach, but with that size comes a set of internal challenges. Yes, they have deep pockets to custom-build systems, have deep integrations, and standardized processes – but they’re also slower to change. Every new initiative has to pass through layers of management, navigate competing priorities, and often gets stuck in internal politics. Teams in one branch might have no idea what’s happening in another. Therefore, good ideas get lost, and decisions drag out.

Smaller and mid-sized distributors, by contrast, are more agile simply because they can be. When they see something that works, they can act on it immediately. Often you still see a lot of time wasted discussing, pitching to management, weighing the pros and cons and going back and forth. While just setting up small experiments, tests, Proof of Concepts or Pilots require very limited resources. I’ve seen small and mid-size companies implement new tools in a matter of days, with minimal friction. There’s no need to sync with five departments or align with global strategies. If it looks like there is significant added value, try it, put the numbers in Excel or – even easier – in an AI model and voila you have (or don’t have) a business case.

Smaller companies also benefit from clearer communication internally, and better rollouts. When something works, the relevant people hear about it. At the biggest distributors there might be a great solution working in one country, market, or department but because of competing interests, layers of decision makers and other factors, a working solution doesn’t get rolled out to all the relevant employees. Or even worse, it just stays within a very small part of the business while there is so much more to be gained.

To get more concrete, there are a lot of areas where distributors can outachieve the largest distributors. The most obvious one is distributors often have an edge when it comes to building relationships. They can be more responsive, more flexible, and more in tune with customer preferences. That service can be taken even further by implementing the right systems that track customer behavior and preferences across channels. Personalized service doesn’t have to mean more manual effort – it can also mean smarter systems that support your sales team with better context and information. Instead of going with the most expensive and well-known CRM’s like Salesforce there are CRM systems specifically developed for distributors (CMG note – CRM systems like LeadSmart and WebPresented, to name two are tailored for distributors.) I’d imagine that the average sales rep at Grainger would be surprised how easy it is to use these systems and what functionalities exist to make their life easier.

Of course, switching CRMs is not easy, regardless of a distributor’s size. There are also smaller processes and solutions which can be implemented within days – instead of weeks, or months. Small experiments instead of big projects as shared in this post before. For example:

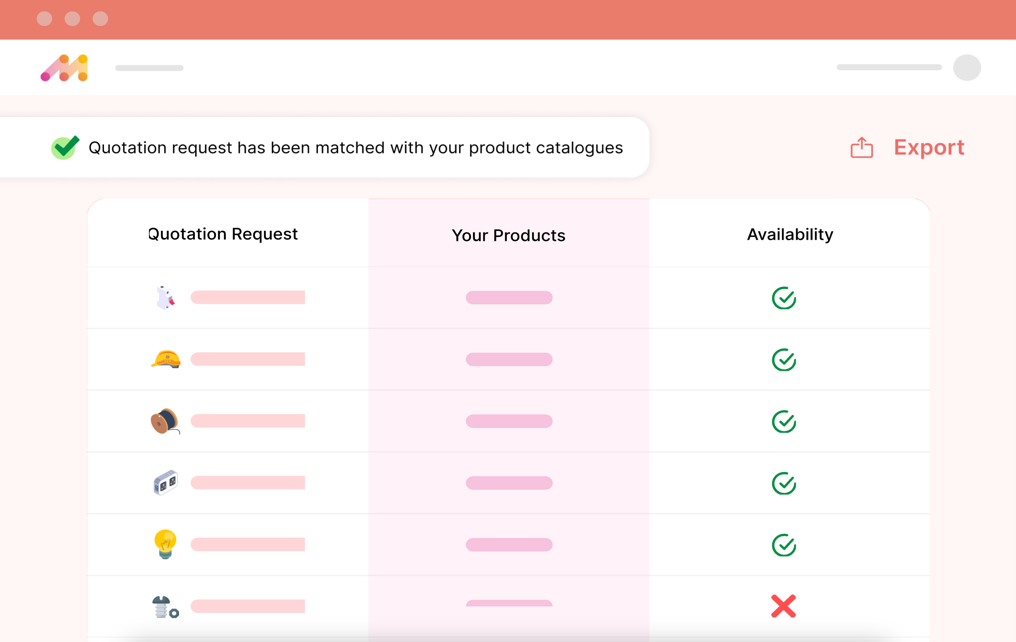

- Quoting processes: I’ve seen distributors run lightweight pilots to speed up response time using smarter cross-referencing tools. Many industrial distributors deal with RFQs that contain hundreds of product lines, with just messy short descriptions and no product numbers or competitor part numbers. Instead of manually looking up equivalents – or worse, telling the customer “We don’t have this” – many companies now automatically match the right products through smart, and easy to implement software like via Mydatafactory which use AI to find the right products. Next to this, saving and using competitor numbers. The result? Less time wasted per quote, a learning solution and a growing database that helps the next request go faster and faster. With solutions like this you have something better than the big players, out of the box. While they have multiple full-time employees managing internally built solutions and databases – you have already responded to the customer while they are just getting started. You can take this even further by not just offering the exact match, but also alternatives with better delivery terms, more stock, or higher margins. Offering an alternative with a better price for the customer turns out to be a deal-winner more often than expected.

- While large players might use massive pricing engines with complex approval flows, other distributors can be, and are, far more nimble. Distributors can introduce solutions for pricing recommendations based on margin, availability, and customer type – not in months, but within a few weeks.

- Reverse Logistics: There’s also a lot of untapped potential in reverse logistics – returns, warranties, and product replacements. In many companies, this process is still handled through email chains and manual entries. But companies have the ability to streamline this through automation. For example digitial workflows where customers can initiate return requests online, track the status, and get timely updates. Internally, the system flags warranty claims, handles vendor credits, and ensures products are returned to inventory or written off correctly. Nex to making life easier for customers – it saves time for internal teams and speeds up resolutions.

These kinds of wins don’t require big change programs. They just require the will to test something and see what happens. That’s the real advantage. Big players often lose time aligning every change across management, business units, and even countries. Smaller companies can simply try something in the morning, adjust it in the afternoon, and have a working solution by the end of the week.

It isn’t about adopting tens of software solutions or building a tech empire. It’s about being more agile, and smarter, where it counts – removing friction from quoting or other processes, being quicker to respond, and offering better alternative products. AI can help, but it doesn’t need to run the whole show (yet). Sometimes it’s just about using it in the right moment to save a lot of typing and clicks or find the right product faster.

Many of the most impactful improvements don’t require major budgets or long implementation cycles – just a willingness to test, learn, and roll out what proves valuable. And once something starts working, momentum builds. A small improvement in one department becomes a new standard. A smarter quoting process leads to faster wins. A simplified returns workflow creates happier customers and fewer headaches. These kinds of changes compound over time.

Note that distributors who embrace this mindset – regardless of their size – are finding themselves more adaptable, efficient and more competitive. In a market where speed, service, and flexibility are often more important than sheer size, that can make all the difference.”

Few companies have access to good cross reference tools, let alone one customized for their needs, and sometimes key vertical markets or specific customers. Mydatafactory can do all this, and more. And the system was easy and cost-effective.

If your company would like to automate finding the right products for RFQ’s and market baskets, contact Timo Bouwers at Mydatafactory. He can be reached at tbouwers@mydatafactory.com.

If your company would like to automate finding the right products for RFQ’s and market baskets, contact Timo Bouwers at Mydatafactory. He can be reached at tbouwers@mydatafactory.com.

More importantly, Timo is attending the NAED National May 20-22 in Marco Island. If you are attending and want to know more, here’s a opportunity to meet, discuss, and learn … and not via another Teams / Zoom call!